What is Metallized Polyester Film?

- Share

- Issue Time

- Apr 26,2023

Summary

Metalized polyester film is a polymer film coated with a thin layer of metal. Read on to learn more about metalized polyester films.

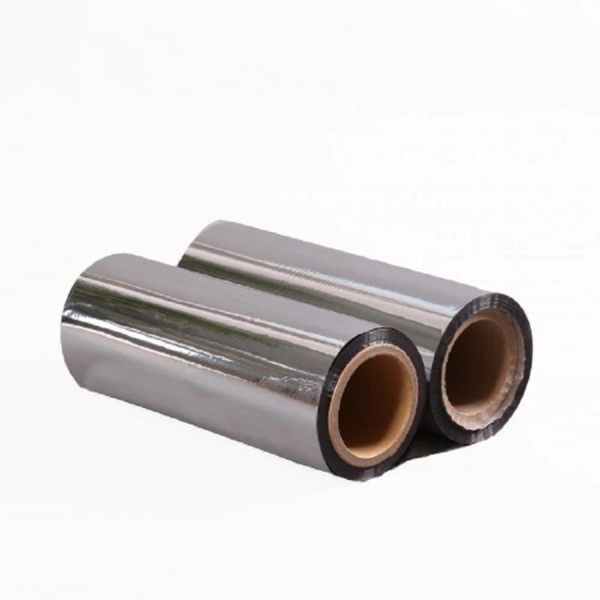

Metalized polyester film (or metalized PET film) is a polymer film coated with a thin layer of metal.

Metallization of polyester films is a proven technology under vacuum conditions. It has special optical properties and reduces the diffusion of gases and odors through the film. The most commonly used metal is aluminum.

The aluminum melt is evaporated by high temperature under a high vacuum. Plastic film surface with a metallic luster. Other metals, such as copper, can also be used.

They provide the glossy metallic look of aluminum foil at a lighter weight and lower cost. Metalized films are widely used for decorative purposes and food packaging. Also suitable for special applications including insulation and electronics.

Metallized Polyester Film Properties

Since the metalized plastic film is coated with a thin layer of metal. It provides a reflective, shiny metallic finish. Food and other goods packaged in this film are more attractive to consumers than food and other goods packaged in printed paper or polymer film.

In addition, our products have many excellent properties. Such as high tensile strength, moisture resistance, heat sealing ability, etc.

Additionally, our metalized polyester film is an environmentally friendly packaging material as it can be recycled. PENGYUAN metalized polyester film is the best solution for high gas barrier and fragrance and taste retention. Due to its high surface energy, high metal adhesion and good homogeneity of the metal layer are achieved. Leads to a significant improvement in high oxygen and general gas barrier properties as well as water vapor barrier properties.

Metalized PET Film Application

Metalized PET film is the ideal solution for all applications where flavor and freshness need to be maintained. It is suitable for many applications in the packaging industry. and applications in technology and industry.

PET film has particular advantages where the higher airtightness of aluminum foil is not required.

Metalized PET film can be printed like aluminum foil. It leads to various optical variants. Metalized PET film is much glossier than aluminum foil. Therefore, a stronger mirror effect can be obtained by using metalized PET film. This is also used when printing.

Therefore, MPET films offer an ideal opportunity to combine certain protective and barrier functions. Its appearance is very attractive. Food protection is not as high as real aluminum foil, and shelf life may need to be shortened.

Metallized Polyester Film Price

PENGYUAN metalized polyester film cost is competitive in the market. If you have more requirements details, you can contact us online or send us an email! We will reply in time and offer you the best price.

Metallized Polyester Film Suppliers

PENGYUAN is a professional custom metalized PET coating manufacturer. We have 3 vacuum coating machines and 8 PE extrusion coating production lines, guided by the 6S management system. PENGYUAN supplies more than 360 million square meters (tons) to global customers every year. Through wider and deeper cooperation, PENGYUAN will continue to focus on the R&D and manufacturing of extrusion coating technology. Committed to becoming an advanced provider of energy-saving new materials and solutions.

Our PE coating metallized PET film have excellent slip and good dimensional stability over a wide temperature range.

Our PE coating metallized PET film have excellent slip and good dimensional stability over a wide temperature range.

Our PE coating metallized PET film have excellent slip and good dimensional stability over a wide temperature range.

Our PE coating metallized PET film have excellent slip and good dimensional stability over a wide temperature range.