Aluminum Foil Composite Packaging Materials with Good Performance Are Widely Used in Many Industries

- Share

- Issue Time

- Sep 7,2022

Summary

Aluminum foil composite materials can improve the barrier properties of packaging, the mechanical strength, and mechanical properties of aluminum foil, and are widely used in the packaging of food, medicine, cigarettes, and other commodities.

Aluminum foil is not only soft in texture, good in ductility, and easy to process, but also lightweight and beautiful, easy to recycle, and environmentally friendly. It is one of the most commonly used materials in modern packaging. In addition, because aluminum foil has high magnetic permeability, good magnetic absorption ability and electromagnetic wave shielding ability, and good heat resistance, it is also often used in the packaging of electronic equipment and semiconductor articles.

Because aluminum foil is easy to form pinholes during packaging and use, which reduces its barrier performance, aluminum foil is often used as a composite material with paper, polymer, or other metal sheets. The practice has proved that aluminum foil composite materials can greatly improve the barrier properties of packaging, and improve the mechanical strength and mechanical properties of aluminum foils.

Aluminum foil composite paper

Using the moisture-proof, rust-proof, gas-barrier, and corrosion resistance of aluminum foil, it can be laminated with paper to become aluminum foil composite paper, or use thermoplastic film as an adhesive to composite aluminum foil and paper together to form multi-layer composite paper. This composite paper combines the high barrier properties of aluminum foil and the folding resistance and impact resistance of paper to become a high-performance packaging material.

Most of the composite components in the material are non-toxic and tasteless materials, which will not cause pollution to the contents and human body, and are easy to meet the hygiene and safety standards of packaging; at the same time, because the resin in it can be decomposed when heated to high temperature, the paper and aluminum foil are separated. , thus greatly improving the recyclability of materials, reducing the waste of materials and the load on the environment.

At present, there are many varieties of this type of aluminum foil composite paper, and different papers can be used according to different needs. Due to the high barrier properties and various packaging adaptability of aluminum-plastic composite paper, it is now widely used in both industrial product packaging and food packaging. In particular, aluminum foil and paper are used for cigarette packaging, which has accounted for 40% to 50% of the consumption of aluminum foil.

Aluminum-plastic composite tank

Aluminum-plastic composite cans are made of aluminum foil, plastic film, and kraft paper (cardboard). Among them, cylindrical aluminum foil composite cans (hereinafter referred to as LFG cans) first appeared in the United States, and now many countries use this packaging form.

LFG cans are characterized by lightweight and low price, about 20% lighter than aluminum cans, about 20% lower cost than tinplate cans, and of course cheaper than aluminum cans; good moisture resistance, sealing, shading for liquid and solid contents High resistance and barrier properties, especially to avoid contamination at the welds of ordinary tinplate cans; moderate stiffness, mechanical strength, high compressive strength, axial crushing force, and end cap detachment force, especially suitable for frozen food packaging.

This composite material also has the characteristics of non-toxic, odorless, and non-polluting contents. It can be reused and recycled. Using it to replace metal sheet cans such as tinplate can avoid pollution caused by metal welds and further reduce costs. and improve economic efficiency.

At present, LFG tanks made of this material have been widely used in the packaging of motor oil and some crisp foods such as potato chips, and will gradually occupy new fields such as pressure vessels and cooking tanks. For example, the strength of the can body and the structure of the end cap are further improved, and the quality of the LFG can is continuously improved, and it can also occupy a place in the liquid packaging container.

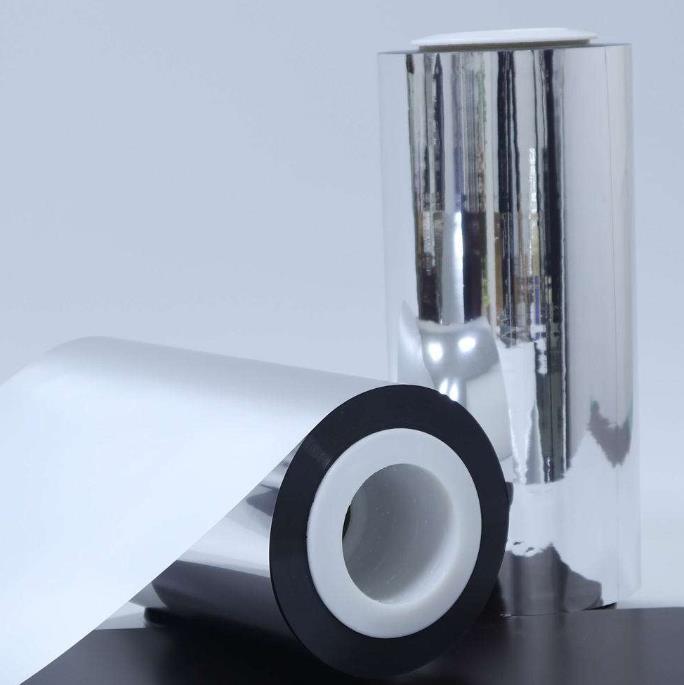

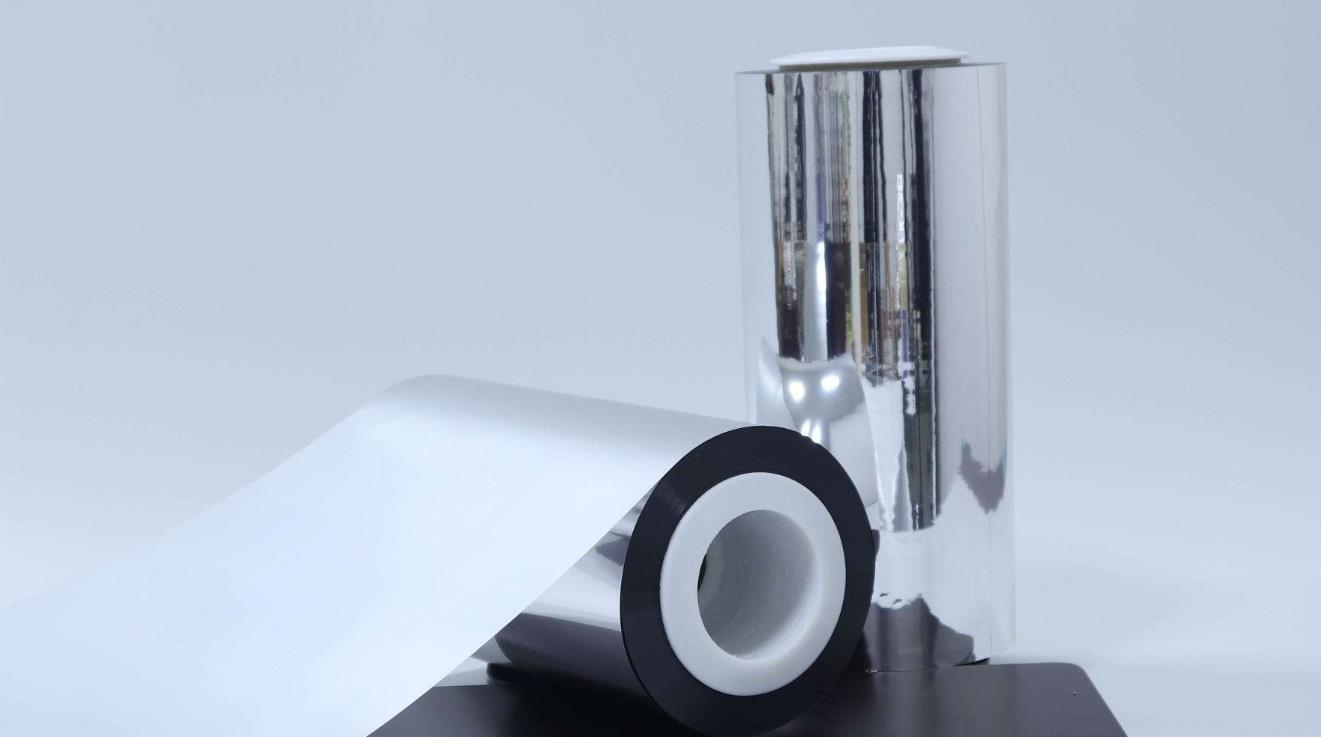

Aluminum-plastic composite soft film

Although aluminum foil is soft and foldable, it has low mechanical strength and poor sealing performance. By compounding aluminum foil with high-strength, heat-sealable plastic film, an aluminum-plastic composite flexible packaging material with excellent barrier properties, mechanical properties, and heat-sealing properties can be obtained. Widely used in food packaging, cooking bags, chemical, and industrial product packaging, and military supplies packaging.

For example, an aluminum foil bag used as a packaging material for soft canned food is a composite material with a three-layer or four-layer structure in which the middle layer is aluminum foil. This kind of aluminum foil bag for soft cans has good mechanical properties and sealing processing properties, good moisture resistance, gas resistance, fragrance retention, oil resistance, and corrosion resistance, non-toxic, odorless, tasteless, hygienic, safe and reliable, and convenient for printing. It is suitable for Automated and mechanized operations and is lighter, more economical, and more energy-efficient than metal cans.

The aluminum foil composite cooking bag is also a widely used aluminum-plastic composite flexible packaging material. It is made of a multi-layer composite of aluminum foil and plastic film. It is a packaging material with air tightness, high barrier properties, high flexibility, and certain heat resistance.

The aluminum foil composite cooking bag has the following advantages: significantly prolongs the shelf life of food, can withstand high-temperature sterilization at 120 ~ 150℃, the shelf life can reach 1.5 to 2 years, can effectively maintain the nutritional level of food, and the color and taste are not damaged. At present, aluminum-plastic composite cooking bags have been widely used in sauce, paste, solid cooking food packaging, and space food packaging.

Aluminum-plastic composite hose packaging material

Aluminum-plastic composite material has good insulation performance, is not easy to break, beautiful in appearance, bright in color, clean and hygienic, is easy to use, is soft on hand, and is good in wrinkle resistance. The hose made of this material is superior to the all-aluminum hose and can be used as a packaging material for toothpaste, ointment, cosmetics, detergents, chemicals, pigments, etc.

Aluminum-plastic composite blister packaging material

The aluminum-plastic blister packaging of medical and health products is also known as blister packaging, referred to as "PTP (Pressthronghpackaging). It is made of barrier plastic blister hard sheets and aluminum foil. The blister packaging of medicines has good protection performance and fast production speed. , low cost, small storage space, lightweight, and low energy consumption for transportation;

It provides patients with a single-dose package of medicines, which is convenient and economical; because the aluminum foil of the blister package is printed with text instructions, the dispenser can avoid the occurrence of wrong medicines and mixed medicines in the distribution of multiple tablets. At present, my country's pharmaceutical industry has greatly increased the production of high-quality blister drugs. It is expected that the materials used for drug blister packaging will account for about 60% to 70% of the packaging materials for pharmaceutical tablets and capsules in the future.

The aluminum foil used in pharmaceutical blister packaging is a sealing material (also called a cover material) sealed on a plastic hard sheet. Moisture-proof and other advantages, it is easy to carry out high-temperature sterilization and can block light, which can protect pharmaceutical tablets from light deterioration.

Before the aluminum foil cover material is sealed with the plastic hard sheet, a text pattern should be printed on a special printing and coating machine, and a protective agent should be applied. The protective agent can prevent the abrasion of the ink and text, and also prevent the contamination caused by the contact between the outer layer of the ink and the inner layer of the adhesive when the aluminum foil is mechanically wound.

The above briefly introduces that aluminum foil composite packaging materials are widely used in many industries. If you want to customize composite aluminum foil, please contact us.

PENGYUAN is a professional custom aluminum foil coating manufacturer. We have 3 vacuum coating machines and 8 PE extrusion coating production lines, guided by the 6S management system. Pengyuan supplies more than 360 million square meters (tons) to customers around the world every year. With wider and deeper cooperation, Pengyuan will continue to focus on the development and manufacture of extrusion coating technology. Committed to becoming an advanced energy-saving new material and solution provider.